4946 Marmora Road, Central New,

United Kingdom

Stainless Steel Forged Fittings

- « Stainless Steel Pipes & Tubes

- « Stainless Steel Fitting

- ◀ Stainless Steel Buttweld Fittings

- ◀ Stainless Steel Forged Fittings

- ○ SS 304/304L/304H Forged Fittings

- ○ SS 316/316L/316Ti Forged Fittings

- ○ SS 309/310/310S Forged Fittings

- ○ SS 317/317L Forged Fittings

- ○ SS 321/321H Forged Fittings

- ○ SS 347/347H Forged Fittings

- ○ SS 904L Forged Fittings

- ◀ Stainless Steel Flanges

- « Stainless Steel Round Bar

- « High Nickel Alloy

Our Products

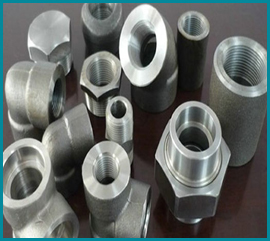

Stainless Steel 316/316L/316Ti Forged Fittings

Stainless Steel 316 Forged Fittings | Stainless Steel 316L Forged Fittings | Stainless Steel 316Ti Forged Fittings Manufacturer

SS 316/316L/316Ti UNS S31600/S31603/S31635 Forged Fittings | SS 316/316L/316Ti DIN 1.4401/1.4404/1.4571 Forged Fittings | ASTM A182 Forged Fittings

JUNGJIN WONIL STAINLESS CO., LTD is a main maker and exporter of Stainless Steel 316, Stainless Steel 316L, Stainless Steel 316H and Stainless Steel 316Ti Forged Fittings that are being composed according to the national and universal standard nature of crude materials and in this manner ensuring their solidness and high caliber.

JUNGJIN WONIL STAINLESS CO., LTD is a main maker and exporter of Stainless Steel 316, Stainless Steel 316L, Stainless Steel 316H and Stainless Steel 316Ti Forged Fittings that are being composed according to the national and universal standard nature of crude materials and in this manner ensuring their solidness and high caliber.

Manufacturing in SS 316 Forged Fittings (WNR 1.4401) and SS 316L Forged Fittings (WNR 1.4432) can deliver a piece that is more grounded than a comparable cast or machined part.

In the interim, we offer a comprehensive scope of stainless steel Forged fittings, for example, SS 316 Screwed Union, SS 316L Screwed Elbow, SS 316H Screwed Tee, SS 316Ti Screwed Cross, SS 316 Weldolet, SS 316L Screwed Bushing, etc.

Additionally refereed as UNS S31600, S31603, S31609 and S31635, these SS 316H Seamless Forged Fittings (WNR 1.4404) and SS 316Ti Forged Fittings (WNR 1.4571) can further be modified as far as thicknesses and sizes according to the particular prerequisites given by our customers.

Specification of Forged Fittings

| Grade | SS 316(UNS S31600) SS 316L(UNS S31603) SS 316Ti(UNS S31635) |

|---|---|

| Werkstoff Nr | 316 / 1.4401 316L / 1.4404 316TI/1.4571 |

| Standard | ASTM A182 / ASME SA182 |

| Specification | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size | ½” NB – 4” NB |

| Pressure | 2000LBS, 3000LBS, 6000LBS, 9000LBS, etc. |

| Type | Socket Weld (S/W) & SCREWED (SCRD) – NPT, BSP, BSPT, Threaded Fitting |

Types of Forged Fittings

| Stainless Steel Socket Weld Caps | Stainless Steel Socket Weld Tee | Stainless Steel Socket Weld Unions |

| Stainless Steel Couplings | Stainless Steel Forged Reducers | Stainless Steel Socket Weld Cross |

| Stainless Steel Socket Weld 90° Elbows | Stainless Steel Socket Weld Full Coupling | Stainless Steel Socket Weld Half Coupling |

| Stainless Steel Socket Weld 45° Elbows | Stainless Steel Socket Weld Reducing Coupling | Stainless Steel Screwed Unions |

| Stainless Steel Screwed 45° Elbows | Stainless Steel Screwed 90° Elbows | Stainless Steel Screwed Tee |

| Stainless Steel Screwed Cross | Stainless Steel Screwed Hex Plug | Stainless Steel Screwed Squared Plug |

| Stainless Steel Screwed Hex Nipple | Stainless Steel Screwed Bushing | Stainless Steel Screwed Full Coupling |

| Stainless Steel Screwed Half Couplings | Stainless Steel Screwed Reducing Couplings | Stainless Steel Screwed Caps |

| Stainless Steel Weldolet | Stainless Steel Sockolet | Stainless Steel Threadolet |

| Stainless Steel Elbolet | Stainless Steel Nipolet | Stainless Steel Latrolet |

| Stainless Steel Concentric Swage Nipple | Stainless Steel Eccentric Swage Nipple | Stainless Steel Forged Pipe Nipple |

Chemical Composition

| C | Mn | Si | P | S | Cr | Mo | Ni | N | |

|---|---|---|---|---|---|---|---|---|---|

| 316 (S31600) |

0.08 max |

2.0 max |

0.75 max |

0.045 max |

0.03 max |

min: 16.0 max: 18.0 |

min: 2.0 max: 3.0 |

min: 10.0 max: 14.0 |

0.10 max |

| 316L (S31603) |

0.03 max |

2.0 max |

0.75 max |

0.045 max |

0.03 max |

min: 16.0 max: 18.0 |

min: 2.0 max: 3.0 |

min: 10.0 max: 14.0 |

0.10 max |

| 316TI(S31635) | - | - | - | - | - | 16.0 | 2.00 | 10.0 | - |

| 0.08 | 2 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | 0.1 |

Mechanical Properties

| Grade | Tensile Strength ksi (min) |

Yield Strength 0.2% ksi (min) |

Elongation % | Hardness (Brinell) MAX | Hardness (Rockwell B) MAX |

|---|---|---|---|---|---|

| 316 (S31600) |

75 | 30 | 40 | 217 | 95 |

| 316L (S31603) |

70 | 25 | 40 | 217 | 95 |

| 316TI(S31635) | 515(Mpa) | 205(Mpa) | 35 | 205 | 75 |

Physical Properties of 316/316L

| Density lbm/in3 |

Thermal Conductivity (BTU/h ft. °F) |

Electrical Resistivity (in x 10-6) |

Modulus of Elasticity (psi x 106 |

Coefficient of Thermal Expansion (in/in)/°F x 10-6 |

Specific Heat (BTU/lb/°F) |

Melting Range (°F) |

|---|---|---|---|---|---|---|

| 0.29 at 68°F | 100.8 at 68 212°F | 29.1 at 68°F | 29 | 8.9 at 32 – 212°F | 0.108 at 68°F | 2500 to 2550 |

| 9.7 at 32 – 1000°F | 0.116 at 200°F | |||||

| 11.1 at 32 – 1500°F |

Physical Properties of 316H

Physical Properties (Room Temperature) |

||

|---|---|---|

Specific Heat (0-100°C) |

500 |

J.kg-1.°K-1 |

Thermal Conductivity |

14.6 |

W.m -1.°K-1 |

Thermal Expansion |

16.5 |

mm/m/°C |

Modulus Elasticity |

193 |

GPa |

Electrical Resistivity |

7.4 |

μohm/cm |

Density |

7.99 |

g/cm3 |